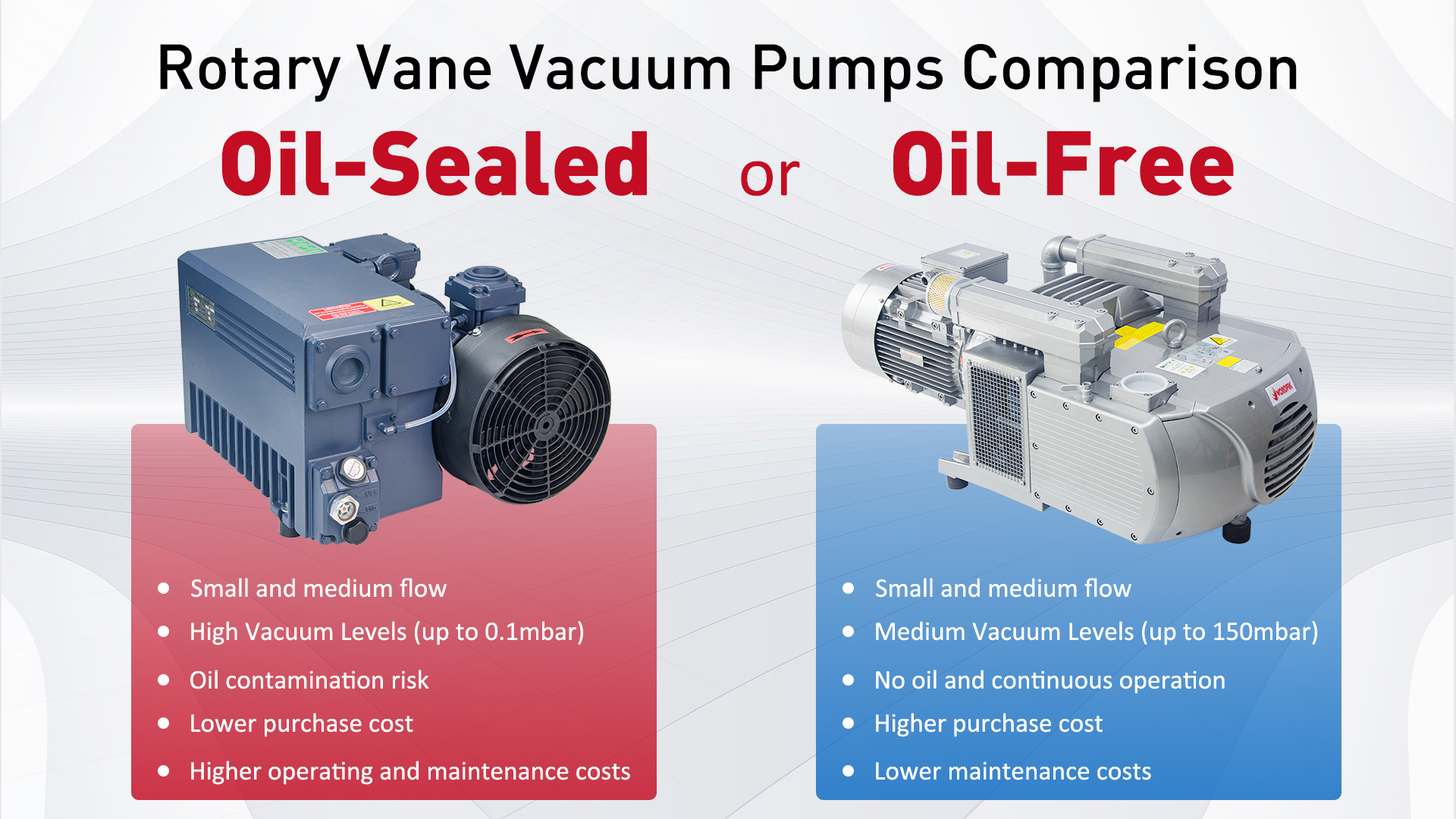

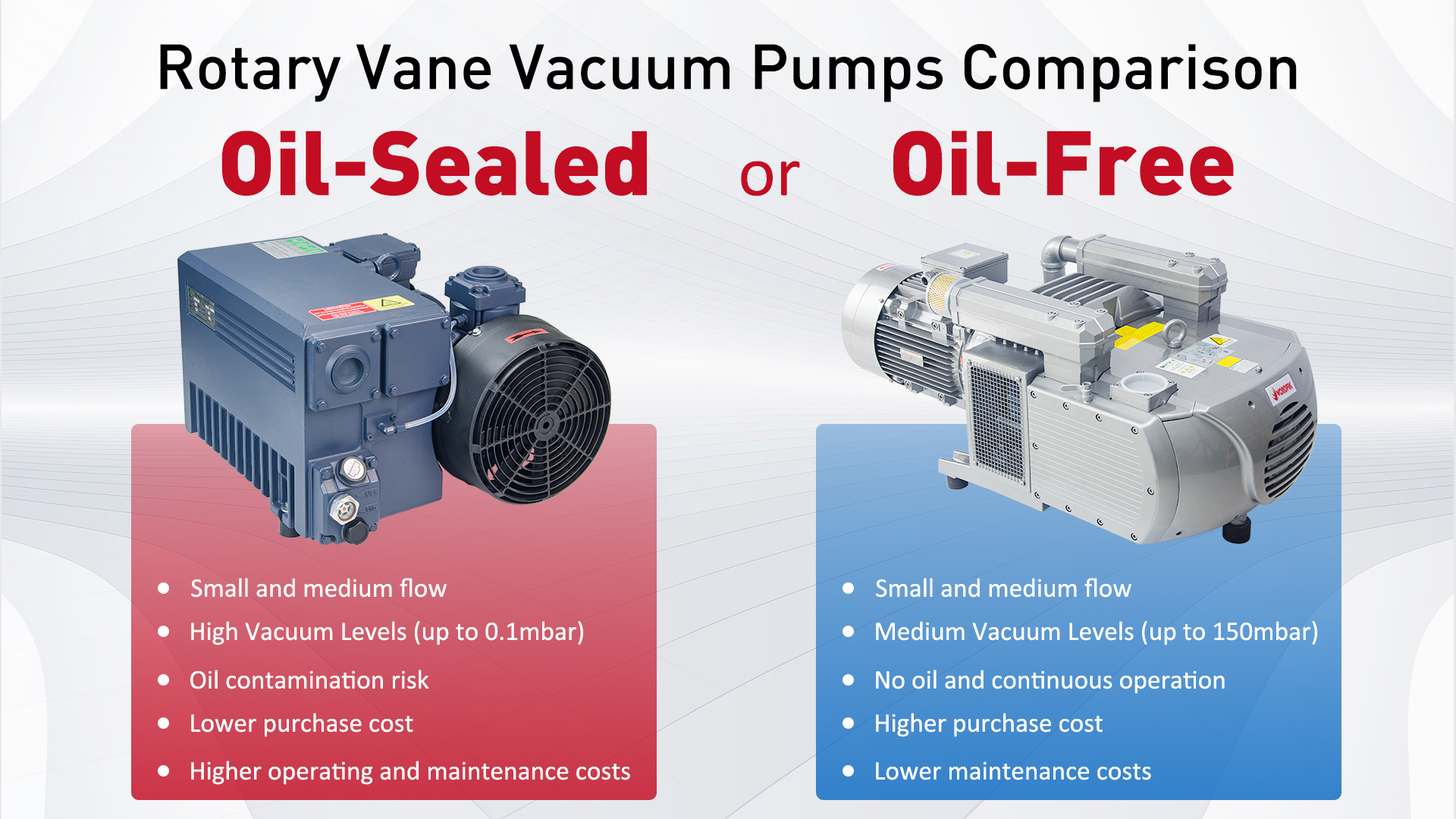

Dry Rotary Vane vs. Oil-Lubricated Rotary Vane Vacuum Pumps: A Selection Guide

In the world of vacuum technology, selection is akin to a precise balancing act. Understanding the differences between dry and oil-lubricated rotary vane vacuum pumps marks the first step toward success.

In industrial manufacturing, scientific research, and laboratory work, rotary vane vacuum pumps are indispensable equipment. However, making the right choice between the two main types—dry and oil-lubricated—directly impacts work efficiency, operating costs, and process quality.

Statistics from practical applications show that improper pump selection can lead to a 30% increase in energy consumption, a 50% rise in maintenance costs, and even a decline in product quality. This article provides a comprehensive selection guide to help you make an informed decision between dry and oil-lubricated rotary vane vacuum pumps.

01. Understanding Basic Principles: The Foundation of Selection

The working principle of rotary vane vacuum pumps is based on a simple yet efficient design: inside the pump chamber, an eccentric rotor rotates, driving multiple sliding vanes. Centrifugal force presses the vanes against the inner wall of the pump chamber.

This action isolates, compresses, and finally exhausts the gas entering the pump chamber, thereby creating a vacuum at the inlet.

Oil-lubricated rotary vane vacuum pumps rely on vacuum pump oil as the working medium. The oil serves multiple purposes: it fills the tiny gaps between the vanes and the pump chamber, providing effective sealing; it lubricates moving parts to reduce wear; and it carries away compression heat, preventing the pump from overheating.

This time-tested design has made oil-lubricated rotary vane pumps the workhorse of industrial applications for many years.

Dry rotary vane vacuum pumps represent technological advancement. They completely eliminate the oil medium, relying on special mechanical designs and material processes to achieve sealing, lubrication, and cooling.

By incorporating self-lubricating materials, low-friction designs, and effective heat dissipation measures, dry pumps operate stably without oil, meeting the stringent cleanliness requirements of modern industry.

02. Five Key Differences: Charting the Selection Path

Working Medium & Contamination Risk

The working medium is the most fundamental difference between the two pumps and directly determines their contamination risk levels.

Oil-lubricated rotary vane pumps require vacuum pump oil as the sealing, lubricating, and cooling medium. The oil forms a sealing layer inside, ensuring effective compression and exhaust of gas. However, the presence of oil also introduces the risk of oil vapor backstreaming and oil contamination, which can affect process outcomes and product quality.

Dry rotary vane vacuum pumps completely solve this problem. The pump chamber contains no oil or other liquid media, relying entirely on mechanical structure and special design for sealing and gas transfer.

This makes dry rotary vane vacuum pumps ideal for applications with extremely high cleanliness requirements, such as semiconductor manufacturing and pharmaceutical production.

Vacuum Level & Pumping Performance

Each type has its performance advantages, suitable for different scenarios.

Oil-lubricated rotary vane pumps typically achieve higher vacuum levels, sufficient for most conventional vacuum needs. The sealing effect of the oil allows the pump to compress gas efficiently, reaching a high ultimate vacuum. Pumping speed is relatively fast, performing excellently, especially when handling large volumes of gas or requiring rapid vacuum establishment.

While dry rotary vane vacuum pumps can also reach relatively high vacuum levels, they may slightly underperform compared to oil-lubricated pumps in applications demanding the highest vacuum levels.

Pumping speed might be somewhat limited due to their more complex sealing structure, which increases gas flow resistance within the pump.

Gas Compatibility & Application Scenarios

Different process gas characteristics directly point to different pump types.

Oil-lubricated rotary vane vacuum pumps have some tolerance for gases containing small amounts of moisture, dust, and other impurities; the pump oil can provide a degree of filtration and adsorption.

However, they are unsuitable for handling gases containing large amounts of corrosive substances or gases that react chemically with oil, as these can cause oil degradation and pump damage.

Oil-lubricated rotary vane vacuum pumps are widely used in food processing, pharmaceuticals, chemicals, electronics, and other industries. For example, they are used in food processing for vacuum packaging and degassing, and in the pharmaceutical industry for drug drying and concentration processes.

Dry rotary vane vacuum pumps, lacking oil, can handle various gases, including corrosive, flammable, and explosive gases. However, filtration measures are still necessary for gases containing large amounts of particulate matter to prevent wear.

Dry rotary vane vacuum pumps are commonly used in semiconductor manufacturing, aerospace, nuclear industry, scientific research laboratories, and other fields requiring high cleanliness and oil-free environments.

Maintenance & Operating Costs

Maintenance requirements and cost structure are crucial considerations in the selection decision.

Oil-lubricated rotary vane vacuum pumps require relatively complex maintenance, including regular replacement of vacuum pump oil, checking oil quality and level to ensure normal pump operation. Attention must also be paid to oil filtration and purification to prevent impurities from causing wear to the pump's internal components.

Dry rotary vane vacuum pumps are relatively simple to maintain. Without oil, there is no need for oil changes or oil-related maintenance. Primary maintenance tasks include regularly checking pump sealing performance, cleaning dust and impurities from the pump, and inspecting the mechanical components for normal operation.

Regarding cost structure, oil-lubricated rotary vane vacuum pumps have a relatively lower purchase cost, with mature technology and simpler production processes. However, due to the need for regular oil changes and related maintenance, operating costs during use are higher.

Dry rotary vane vacuum pumps have a relatively higher purchase cost, requiring advanced manufacturing processes, technology, and special materials and structural designs. But with simpler maintenance and no need for oil changes, long-term operating costs may be relatively lower.

Environmental Impact & Sustainability

With increasingly strict environmental requirements in modern industry, environmental performance cannot be ignored.

Oil-lubricated rotary vane vacuum pumps may generate oil mist during operation, causing some environmental pollution. If oil leaks or is improperly discharged, it can contaminate soil and water sources. Waste vacuum pump oil requires specialized disposal; otherwise, it poses environmental hazards.

Dry rotary vane pumps are oil-free vacuum pumps, producing no oil pollution during operation, making them more environmentally friendly. This characteristic aligns with modern industrial environmental requirements, leading to their widespread use in industries and locations with high environmental standards.

03. Practical Selection Guide: Making an Informed Decision

Matching Pump Type to Process Requirements

Selecting the most suitable pump type for a specific application requires considering multiple technical factors. The following comparison table clearly shows the main characteristics and application scenarios of the two pumps:

| Characteristic | Oil-Lubricated Rotary Vane Vacuum Pumps | Dry Rotary Vane Vacuum Pumps |

| Ultimate Vacuum | Higher (e.g., down to 0.06 Pa level) | Medium to High (e.g., 1.5 Pa level) |

| Pumping Speed | Faster | Limited by complex sealing structure |

| Contamination Risk | Possible oil vapor contamination | No oil contamination |

| Gas Compatibility | Not suitable for corrosive gases | Can handle corrosive, flammable, explosive gases |

| Maintenance Needs | Regular oil changes, relatively complex | Simple, no oil-related maintenance |

| Purchase Cost | Lower | Higher (approx. equivalent to two oil-lubricated pumps) |

| Operating Cost | Higher (due to consumables & maintenance) | Lower (long-term use) |

| Typical Applications | Food packaging, general laboratories | Semiconductor manufacturing, research labs |

Focus on Key Performance Parameters

Beyond pump type selection, attention to specific performance parameters is necessary to ensure they meet actual needs:

Pumping Speed: Indicates how many liters of air can be pumped per second. The selection should be based on the volume of the system being evacuated and the required evacuation time.

Ultimate Vacuum: The lower, the better, especially for stringent applications like resin degassing.

Motor Power: Typically ranges from 150W to 1500W. Higher power generally means better continuous operation capability, but a balance between efficiency and energy consumption must be struck.

Consider Total Cost of Ownership

When selecting, don't focus solely on the initial purchase price; consider the total cost of ownership over the entire lifecycle. While oil-lubricated pumps have low initial investment, the long-term cumulative cost of oil changes and maintenance is significant.

Although dry pumps have a higher initial price, they save ongoing oil costs and some maintenance downtime, potentially proving more economical in the long run.

Also consider the value of equipment downtime. For continuous production processes, pump reliability directly impacts production efficiency and product quality.

04. Maintenance Essentials: Ensuring Long-Term Performance

Maintenance Points for Oil-Lubricated Rotary Vane Vacuum Pumps

The key to maintaining oil-lubricated rotary vane pumps lies in oil management. Regularly check oil level and quality; replace oil promptly if it discolors or becomes emulsified.

The oil change interval is typically every 500-2000 operating hours, depending on the usage environment and conditions. For pumps operating in humid environments, use the gas ballast valve (if equipped) to prevent water vapor from condensing and mixing with the oil inside the pump.

During prolonged shutdowns, close the inlet valve to prevent atmospheric moisture from entering the pump and causing corrosion. Regularly cleaning the oil filter screen and replacing the exhaust filter are also important measures to maintain pump performance.

Maintenance Points for Dry Rotary Vane Vacuum Pumps

Although dry rotary vane vacuum pumps require no oil-related maintenance, regular checks of sealing performance and cleaning of dust and debris inside the pump are still necessary.(Wordfik offers external filters that significantly extend maintenance time)

For dry pumps using special sealing materials, inspect the seal condition according to the manufacturer's recommended schedule. Keeping the cooling system unobstructed to ensure the pump does not overheat is key to guaranteeing long-term stable operation.

During daily operation, monitor changes in pump noise and temperature, as abnormal changes are often precursors to failure. For electrical components, ensuring secure connections and good ventilation can prevent many potential problems.

The essence of selecting a vacuum pump lies in finding the optimal balance between technology and economics. Regardless of which type of rotary vane vacuum pump you choose, correct maintenance and usage habits are crucial for ensuring long-term stable operation. A rational choice doesn't seek the most expensive or the newest technology, but rather the solution that best fits your actual needs.

On the path of vacuum technology, there is no one-size-fits-all answer, only the most suitable application match. This is precisely the wisdom of selection.